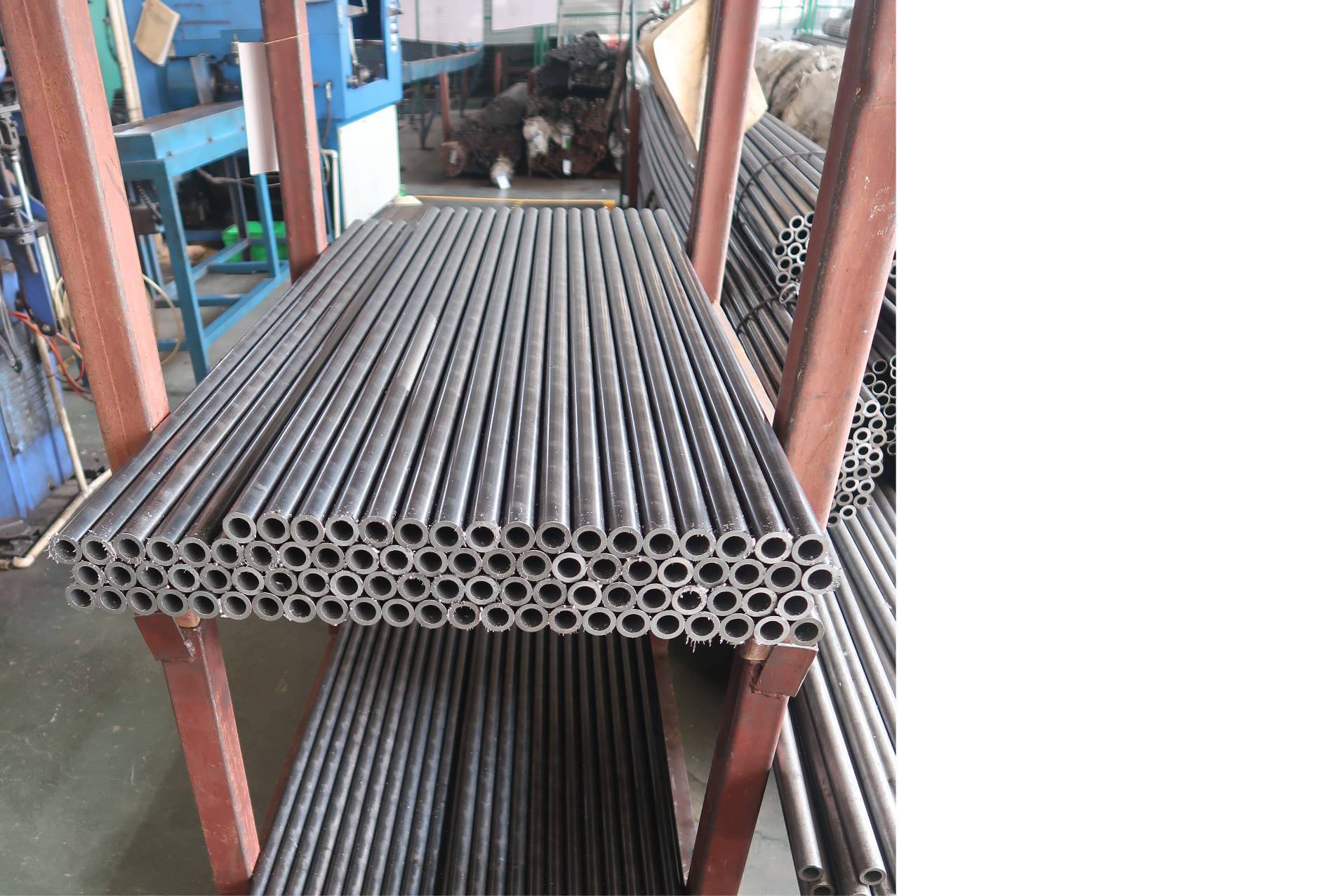

Raw sway bar materials in our daily production line.

The differences caused by varying sway bar raw materials, structured for clarity and impact

**Technical Version (For Engineers/Manufacturers):**

"The quality of sway bar raw materials directly determines the component's fatigue life and performance. We start with premium alloy steel billets (typically SAE 4140 or 4340) that undergo rigorous metallurgical testing for grain structure, hardness, and inclusions. Properly sourced bar stock ensures consistent mechanical properties after heat treatment, preventing premature failure under torsional stress."

**Supplier/Procurement Focus:**

"Selecting the right sway bar feedstock is a critical first step in our value chain. Our raw material specifications require:

- Traceable mill certifications

- Controlled chemical composition (e.g., Cr-Mo alloy content)

- Ultrasonic testing for internal defects

This due diligence minimizes downstream rework and warranty claims."

Let me know if you'd like to emphasize specific aspects like cost control, sustainability, or testing protocols!

+86-571-88843231

+86-571-88843231