Why do sway bars require a full set of matching parts?

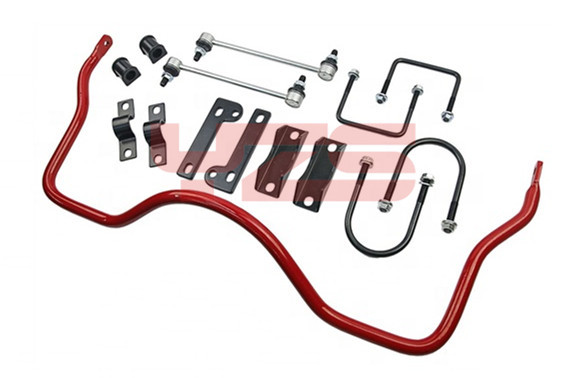

A sway bar (also called an anti-roll bar or stabilizer bar) typically requires a complete set of matching components to function safely and effectively. Here’s why:

Balanced Performance

The sway bar works by transferring force from one side of the suspension to the other during cornering, reducing body roll. If components like end links, bushings, or mounting brackets are mismatched or worn, it can lead to uneven stiffness, causing unpredictable handling or reduced effectiveness.

Load Distribution & Durability

The bar is subjected to high torsional stress. A full set of properly engineered parts ensures stress is evenly distributed. Weak or incompatible parts (e.g., end links too long/short, soft bushings) may cause premature failure, noise, or damage to other suspension components.

Safety & Reliability

A partially upgraded or mismatched sway bar system can create stress concentrations or alter suspension geometry unexpectedly. This might affect tire contact or stability, especially in emergency maneuvers. Complete kits are designed to work together, ensuring predictable vehicle behavior.

Installation Compatibility

Manufacturers design sway bar kits with specific dimensions, hardness, and attachment points. Mixing random parts can lead to fitment issues, misalignment, or excessive preload, negating the benefits of the sway bar.

Optimized Tuning

Performance-oriented kits often include adjustable end links or multiple stiffness settings. Using a matched set allows for fine-tuning while maintaining harmony with the vehicle’s suspension design.

Contact Person

- Name:

- Jessica

- Tel:

+0086-576-87221128

+0086-13736677602

- WhatsApp:

- 8613736677602

- Address:

- Building 62, Chuangrong Industrial Zone, Yucheng Street, Yuhuan, Zhejiang 317600

subscription

Signup for our newsletter to stay up-to-date on our promotions, discounts, sales, special offers and more

+

+